Induction lamps are a type of High Output Fluorescent lamp that are known as Electrode less Fluorescent Discharge Lamps or EFDL for short. Unlike conventional lamps which require screw in sockets or pins to power up the lamps, the EFDL induction lamp does not rely on a socket or pin connection to power the lamp. Instead EFDL efficiencies derive from being powered by a High Frequency Electromagnetic Field. Without the use of pins, sockets or ballasts to operate the lamp, more energy is converted into usable plant light and not wasted due to the high temperatures and escaping gas inefficiencies that is inherent of lamps requiring electrodes.

Induction lighting is on the expensive side, but offers an excellent choice for both vegetative and flowering growth. Some growers complain about their intensity compared to HID lighting and compare yields similar to LED lighting.

- Saves up to 70% in electrical loads.

- Emits 95% PAR usable light.

- Excellent canopy penetration.

- Faster rooting of clones and seedlings

- Long life lamps and drivers.

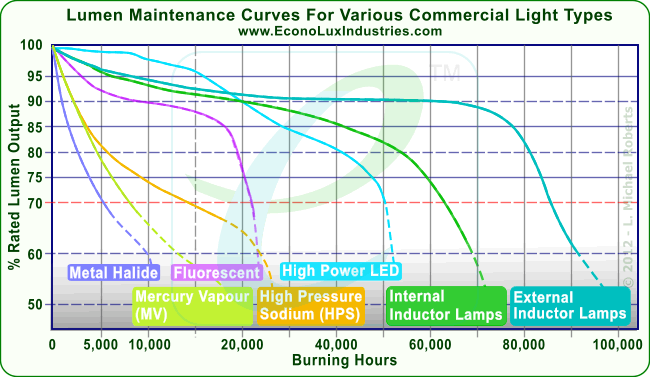

- ~100,000 hour life which is 10 to 20x longer than that of a High Pressure Sodium or Metal Halide bulb

- Highest lumens per watt of any lamp manufactured.

- Single lamp for vegetative through flowering stages.

- Low operating temperatures require no added ventilation.

Induction Lamps vs. HID Lamps

- HID Lighting technology uses electrodes or filaments, which are embedded through the lamp envelope (glass/quartz) to bring an electrical current to the interior of the lamp. Induction lighting uses advanced technology to produce high quality light from a lamp that lasts for up to 100,000 hours of operation. The completely sealed lamp envelope has no filaments or electrodes to burn out. Power is transferred to the interior of the lamp by means of a strong magnetic field generated by inductors which are external to the lamp wall.

- With conventional HID lighting, the points where the wires for the filaments or electrodes pass through the wall of the lamp, are subject to thermal stresses due to the heating and cooling of the lamp. Over time, this causes micro cracks which can allow atmospheric gasses to enter the lamp contaminating the interior. In addition, the filaments or electrodes are heated by the passage of the electrical current causing them to evaporate over time. For example: The black rings often seen around the ends of fluorescent tubes are caused by the condensation of evaporated metals from the filaments.

- Induction lamps are completely sealed and have no filaments or electrodes penetrating the lamp walls. There is no possibility of thermal stress at the places where wires penetrate the light walls as there are no wires, and there are no filaments or electrodes inside the lamp to evaporate.

- Induction bulbs are 5x larger than an HID bulb, so they can deliver the same kind of intensity found at the source of an HID bulb, but over a much longer and wider area. HID lamps need to be hung around 20 inches away from the canopy due to excessive heat

- Due to excessive heat, HID lamps need to be hung around 18 to 20 inches away from the canopy which allows for about 3ft of intense light penetration. Induction lamps on the other hand can be hung around 6 to 8 inches from the canopy allowing for about 6 ft of even and intense penetration. PAR tests indicate that a 400 watt induction lamp at 6-8 inches from the canopy is equivalent to a 1000 watt HID at 18-20 inches above the canopy.